COSTRAL is the long-standing partner of leading FRENCH labelling manufacturer, ALBAGNAC.

This alliance enables us to offer Made in France solutions for customised labelling for your bottles.

Customised labelling for your bottles

ALBAGNAC machines offer adhesive, rotary or linear labelling solutions, from 0 to 6,000 bottles / hour. A range on which we have become experts, thanks to our 30 years of partnership.

Whatever your business, our adhesive labellers adapt perfectly to all types of containers, shapes and caps. ALBAGNAC labellers provide both capping and/or labelling for filled bottles, as well as jars or other containers you may

need.

In Still Wine mode

Prior to labelling, ALBAGNAC machines are able tocap bottles.

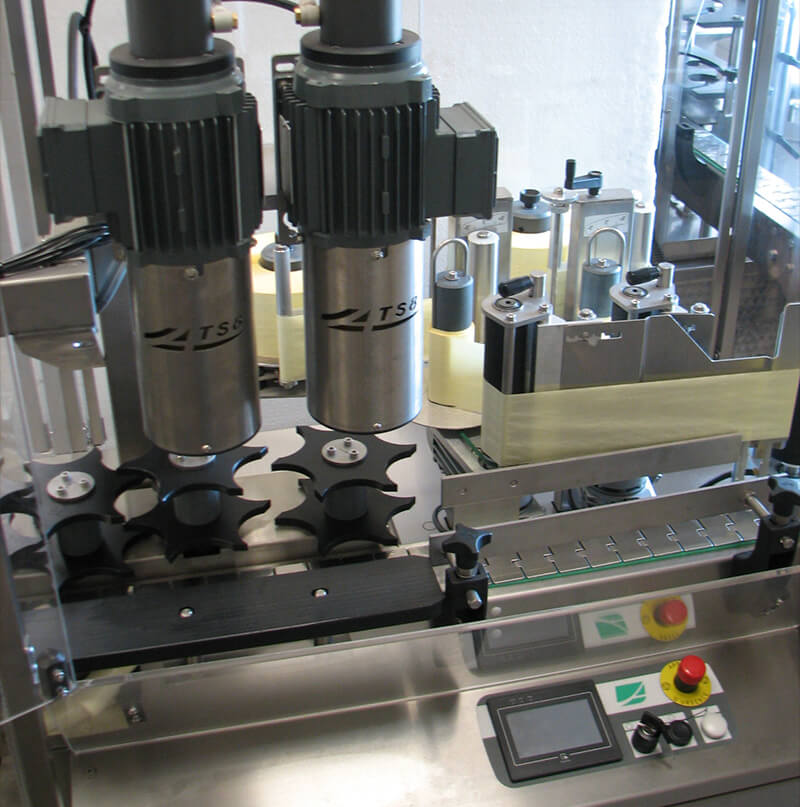

They have an automated capping dispenser with a long-range loading magazine (inclined plane), neck centering clamp and ejector-insertion driver.

The capping station has a slow descent and fast ascent (short low neutral position) and a crimping head with eight rollers (mounted on ball bearings) of TS 8 for standard aluminium, tin or complex

metal caps.

The bottles are then transported to the labelling unit, where they are secured by a pneumatically operated door that rotates during the labelling process. In order to provide perfect finishes, the machines have a

star sensor to detect the bases by notching the bottles. This system can position labels centrally in line with glass engraving.

In Champagne mode

ALBAGNAC machines can be fitted with a automated Champagne cap dispenser and a long-range loading magazine (inclined plane).

Bottles pass through a pneumatic door and are rotated using a motorised roller (managed by a frequency converter) in order to be detected by cell for a spot on the Champagne

caps. They are then secured and positioned before being transferred to the smoothing head. The capping station with fast descent and ascent (long low neutral position) has a crimping head with inflatable lined pockets (four-ply pre-folding; final smoothing) for “Champagne” caps.

The bottles are finally sent to the labelling unit, where they are secured by a second pneumatically operated door that rotates during the labelling process. To ensure labels are positioned centrally in relation

to the Champagne cap, the machines use a new detection device, by cell from thespot of the Champagne caps.

Adhesive labelling

Adjustments during labelling is carried out using a coloured touch screen which can memorise the settings relating to each type of bottle and label. The labels are automatically calibrated at the end of the release plate (regardless

of the width of the labels). The bottles arrive on a rectangular 500 x 500mm stainless-steel accumulation table at the outlet. To control the labeller, there is a built-in stainless steel electric box with low-voltage controls.

The basic machine can be set up to apply a self-adhesive body label and back label (two adhesive stations), on a cylindrical Still Wine bottle format and/or cylindrical Crémant bottle format.

It is possible to installtwo juxtaposed dispensers (caps and Champagne caps), with two TS 8/CHAMP capping stations, two directions per reading for a spot.

The major advantages of our labelling machines

- Labelling stations adjustable in height by crank and tilting (+/- 8°)

- Anodised aluminium profile frame

- Machine mounted on four height-adjustable feet

- 1000mm long entry conveyor

- Safety protective Plexiglas fitted to the capping stations, meeting the regulated standards in force (CE standards).

- Entry bottle selection by stars.

- Cycle stops in the event of a missing label.

A personalised service thanks to COSTRAL Services

COSTRAL Services is by your side throughout your project, from installation to operator training.

Every machine is supplied with a general maintenance guide.

We provide a specially dedicated free hotline offering After-Sales service and dealing with queries concerning the functionality of your COSTRAL machine.

Contact us directly on +33 (0)3 89 47 89 45.